ARBA FÉMTECH KFT.

A NEW DIMENSION OF METALS

Arba Fémtech Kft. was established in 2011 in close cooperation with our German partner company BJM Verwaltungs GmbH at our leased premises located at 50 Szoboszlói út in Debrecen.

Initially, our company focused on the production of tools, gradually moving into sheet metal working with 2 flat bed lasers and 2 edge bending machines.This sheet metal working initiative has been so successful, thanks to the developments, that after lengthy negotiations and thorough discussions, we have been offered the opportunity to become a supplier to a premium German car manufacturer.

For several years afterward, ARBA Fémtech Ltd. produced several types of small and medium series as well as a product of outstanding complexity in large series.

Other technologies have been introduced later, such as CNC turning, CNC milling, punching, welding (AWI and CO), spot welding, stud welding, design, appliance manufacturing, locksmithing, plate rolling, gluing, grain spraying, assembly and surface treatment (galvanizing and powder coating).

In 2017, we decided to set up our own site and the Nyugati Industrial Park in Debrecen provided the ideal opportunity.

In 2019, in the spirit of the company’s further development, Pál Szabó, who had already played an important role and demonstrated his commitment countless times, took over the management and brought with him his continued drive.

In 2021, we implemented ISO 9001 Quality Management System and also in this year we began the introduction of the IPS ERP system, which was developed specifically for our operations.

In May 2023, operations were fully relocated to the aforementioned site, allowing us to centralise all aspects of engineering preparation and manufacturing in a single location. Our new site features a hall with an area of 2100m2, providing excellent conditions for the entire production process.

Our diverse client base has given us extensive experience in the field of metalworking for more than a decade.

Our clients range from small and medium-sized enterprises to large multinationals, which is testament to our ability to adapt and meet all needs.

We are active in the following industries:

- Agricultural Industry

- Mechanical Engineering

- Automotive Industry

- Electronics Industry

- Construction

- Food Industry

- Customized Component Manufacturing

In addition to further strengthening our role in the eastern region of Hungary, our goal is to become a leading player in our industry nationwide and to be a force in the international market.

Our Services

Our company offers complex sheet metal processing services. From cutting, bending or customized sheet metal processing, we are ready and available. Using our modern technologies and experienced professionals, we guarantee high quality work and respect of delivery deadlines. You can count on us to provide you with a complete and reliable service in the field of sheet metal working. Our company provides excellent conditions for the production of small, medium and large series.

Laser Cutting and Punching

CNC laser cutting uses a combination of computer-controlled technology and a laser beam to cut a variety of materials with precision and accuracy. Laser cutting machines allow designers and manufacturers to create intricate patterns. There are many advantages to laser cutting, such as fast cutting speed, high accuracy, excellent repeatability and minimal material loss. This technology is suitable for a wide range of applications from prototype production to mass production.

Machinery fleet

TRUMPF L3030 – 4 Kw

3000 × 1500 [mm] range of movement

Cuttable plate thickness 20 [mm]

TRUMPF L2530 – 2 Kw

2500 × 1250 [mm] range of movement

Cuttable plate thickness 12 [mm]

TRUMPF TRUMATIC 600L – 3 Kw

2500 × 1250 [mm] range of movement

Cuttable plate thickness 3 [mm]

Edge Bending

CNC edge bending is a modern machining process that uses a computer-controlled bending machine to precisely and repeatably bend sheet metal parts. This technology allows the creation of complex geometries, optimising the manufacturing process and ensuring a precise end result.

Machinery fleet

TrumaBend 5170

bendable length 3000 mm,

170T maximum plate thickness 10 [mm]

TrumaBend V230

bendable length 3000 mm,

230T maximum plate thickness 10 [mm]

TrumaBend V85

bendable length 2000 mm,

85T maximum plate thickness 3 [mm]

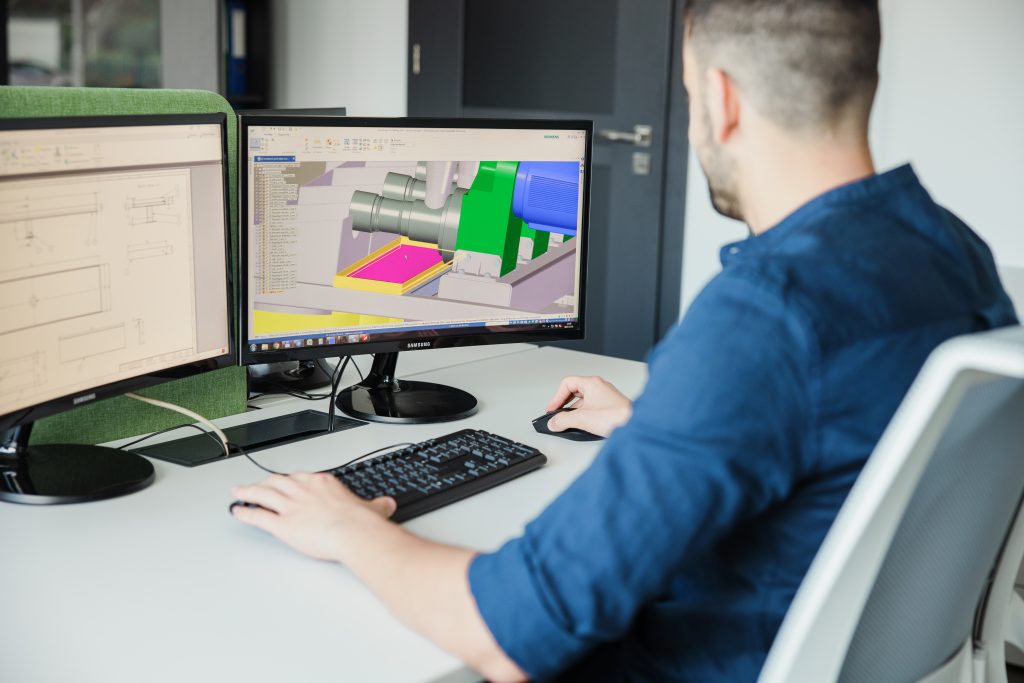

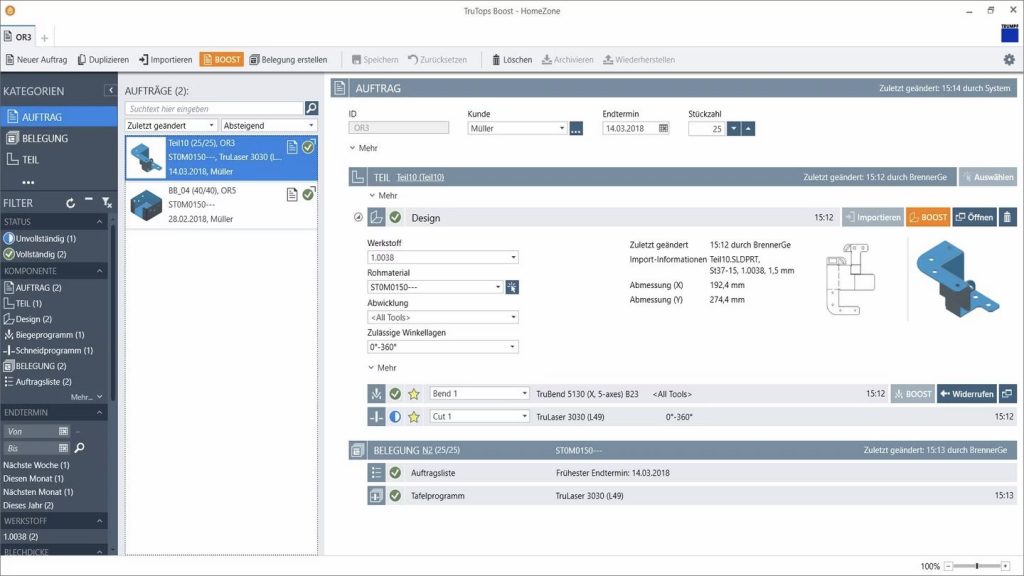

Designing

Laser sheet metal cutting is a computer-controlled manufacturing process for which accurate computer drawings (DXF) are essential. If such drawings are not available or the product you are designing is only conceptual, do not worry! Our experienced design team is ready to help you create the drawings you need, ensuring efficient and accurate laser sheet metal cutting.

CNC Milling and Turning

CNC milling is a computer-controlled manufacturing process in which a milling tool is used to remove excess material from the workpiece by milling it into shavings. Using computer control allows for precise and repeatable work.

Machinery fleet

QUASER-MV-154P

Number of axes controlled: 3

Working range X-Y-Z axis:

760 × 530 × 560 [mm]

Worktable length and width:

900 × 500 [mm]

DECKEL MAHO – DMU 200 P

Number of axes controlled: 4

Working range X-Y-Z axis:

1800 × 2000 × 1100 [mm]

Worktable length and width:

1700 × 1400 [mm]

Welding

- Aluminium welding

- Stainless steel welding

- AWI and CO welding

- Spot welding

- Threaded stud welding

Machinery fleet

FRONIUS Transpuls Synergic 4000 Inverter shielded arc welding machine

(3 pieces)

FRONIUS MagicWave 3000 digital DC/AC three-phase welding machine

(2 pieces)

Hydraulic pressing

Cutting

Locksmith work

Rolling

Threading

Delivery

Production of equipment

Gluing

Sandblasting

Assembly

Surface treatment

Hydraulic pressing

Cutting

Locksmith work

Rolling

Threading

Delivery

Production of equipment

Gluing

Sandblasting

Assembly

Surface treatment

Our Team

We can confidently say that the real strength of Arba Fémtech Kft. is our high level of professional management and our skilled team of more than 40 people, who have been working in perfect coordination for many years.

We place great emphasis on keeping our employees’ professional skills up to date, and to this end we regularly send our employees on secondments in close cooperation with our German partner. In addition to professional challenges, they also gain valuable experience and knowledge. Upon returning home, these fresh perspectives and methods will help our company to develop and innovate in the Hungarian market.

Contact us

Our mission is to pursue a sustainable growth path while promoting value for our employees and customers. We are therefore committed to site expansion and machinery upgrades to increase productivity and efficiency.

We also pay particular attention to the continuous improvement of working conditions and the development of our employees, providing them with the right tools and support to succeed.

Our aim is to create an inspiring and stimulating working environment where all our employees have the opportunity for professional and personal development, contributing to the long-term success of both the company and the individuals.

Our Quality Management Policy

Customer focus:

We aim to ensure customer satisfaction and long-term loyalty. With the support of our professionally trained staff and a thorough understanding of customer needs, we strive to meet our customers’ expectations and requirements in every aspect.

Quality and standards:

We strictly comply with the ISO 9001:2015 standard and our production processes are regularly reviewed and improved.

Deadlines:

For us, meeting deadlines without compromise is essential, so we maintain relationships with a wide range of suppliers, making it easy to handle even the toughest purchases and deliver a complete product to our partners.

DO YOU HAVE ANY QUESTIONS?

Minimum order amount: net 15,000 HUF or 40 EUR.